Biodiesel as an alternative liquid fuel-The Monash Fuel from Waste team

BY BRIAN JONG, VICE-PRESIDENT OF MONASH ENERGY CLUB

Growing up, like many other people, cars were a luxury item that required time and effort to purchase. People then typically kept their cars for a significant amount of time, only replacing it when it became unusable. This practice typically holds true today as well, so it is difficult to expect that people will be readily able to transition to electric or hydrogen vehicles, on the scales that would be necessary to have a significant and immediate effect on climate change. There is therefore a need for the use of traditional liquid fuels to be reduced and replaced with sustainable and more environmentally friendly alternatives

The use of alternative fuels will provide a better opportunity and more time to phase out the use of liquid fuels. This will also allow additional time for electric and hydrogen vehicle technology to mature and become more affordable and widespread. Even with eventual replacement by electric and hydrogen vehicles, continued development of alternative liquid fuels will ultimately still be required, as high-powered transportation methods, such as aviation, cannot yet be easily satisfied through the use of batteries.

To aid in the development of sustainable alternative fuels, a student team has recently been created that will look at producing biodiesel: Monash Fuel from Waste. It as an initiative by the Chemical Engineering Department, organised by A/Prof Victoria Haritos, that I have now been fortunate enough to become apart of. The team will look at producing biodiesel, with the use of the oleaginous yeast, Yarrowia lipolytica, to convert residual sugars and nutrients in food waste into lipids, that can be subsequently used in biodiesel production. As an oleaginous yeast, Y. lipolytica is ideal for biodiesel production as it can become very “fatty”, building up a high amount of lipids from different feedstocks.

Y. lipolytica under the micrscope

Growth cultures of Y. lipolytica

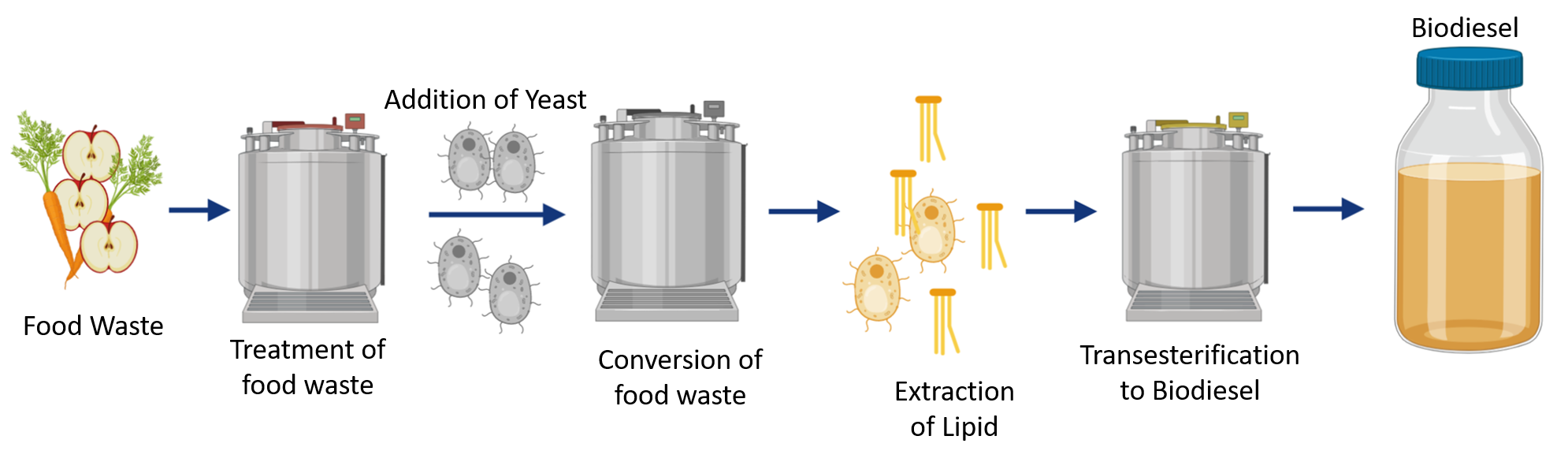

Different studies have already looked at using Y. lipolytica for biodiesel production. However, using food waste as a feedstock for the process would be a new approach. A number of different processes are required the allow the conversion of nutrients and sugars in food waste to the final product of biodiesel:

Food waste will be sourced and pre-treated before being fed to Y. lipolytica

Y. lipolytica will grow on the food waste and produce lipids intracellularly

Cells will be lysed to extract the lipids

Lipids can then be converted into biodiesel through the standard transesterification reaction

Monash Fuel From Waste Biodiesel Production Process

The process being employed by the team differs from typical methods that utilise waste cooking oil as a source. Food waste is not a conventional feedstock for biodiesel production but is readily available in supply. Through the use of food waste, it is planned that the team will be able to demonstrate a solution to various issues related to sourcing viable feedstocks for the production of biodiesel.

Through developing this process, the team also hopes to establish a circular economy around food waste. Food waste will be used in the production of fuel, the fuel will then be combusted producing CO2 and the CO2 will then be consumed in the growth of food crops to produce food. As the team grows and improves the production process, we will also be able to take complete advantage of the Victorian Government’s introduction of an organic waste bin.

Monash Fuel from Waste is still a new team, continuously undergoing rapid development and growth. However, the team has high aspirations and goals for the future, so watch this space! If you have any questions about the team, please feel free to send an email to fuelfromwaste@monash.edu.